New wheel motor and brake solutions for mobile applications

Since 1959, Black Bruin has been perfecting hydraulic wheel drives for long service in the toughest conditions. By helping OEMs develop more efficient machines, we make it possible for end users to increase productivity and work sustainably throughout the season. Today, the company continues to strengthen its offering for the mobile machinery with a new wheel hub motor and an extended range of brake options. These new solutions are designed for tractor-driven agricultural, forestry and construction applications, such as slurry tankers, silage wagons, forestry trailers, harvesting machines, and balers. They are also well suited for other off-highway equipment requiring additional traction, durability, and ease of maintenance.

Black Bruin will showcase its latest innovations at Agritechnica 2025, the world’s leading agricultural machinery exhibition, at stand 17G21.

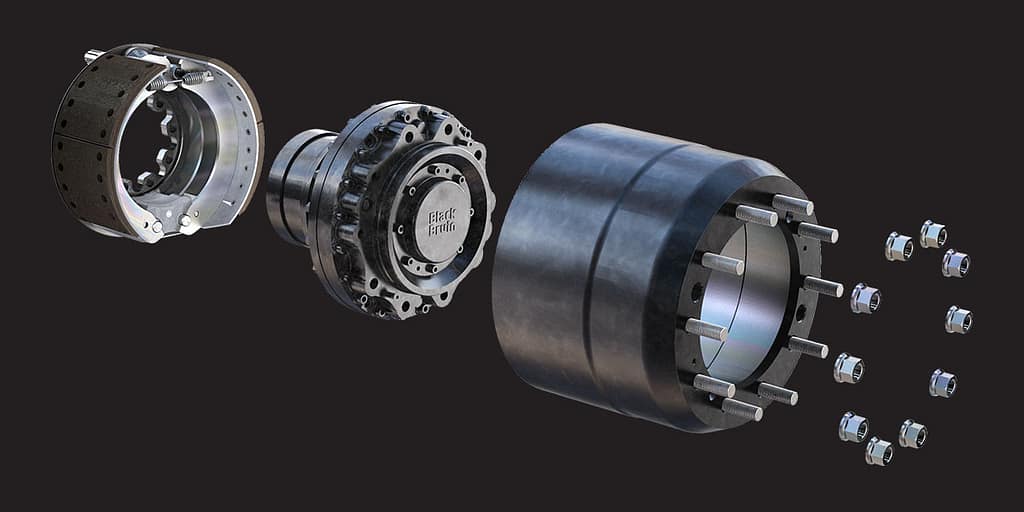

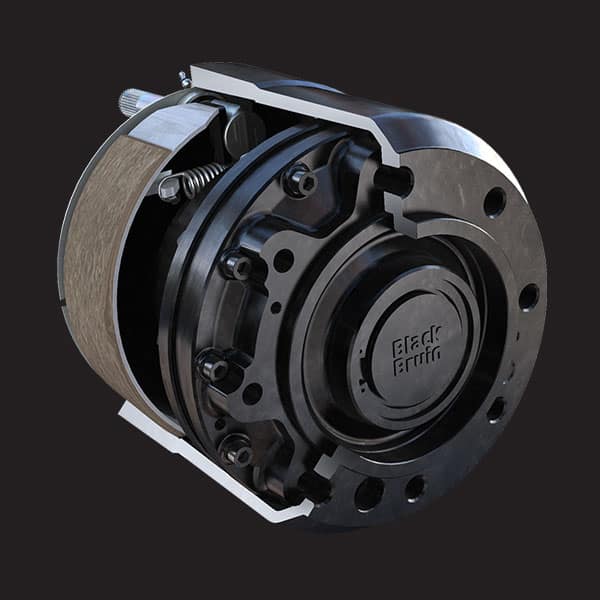

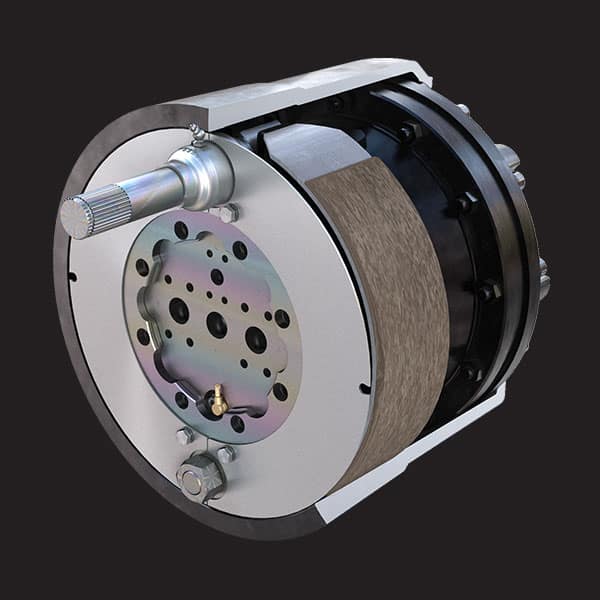

BM60 Wheel Motor

The BM60 is a radial piston motor featuring Black Bruin’s distinctive rotating housing design. Combined with its robust bearing construction, it provides high load-carrying capacity, compact dimensions, and easy installation inside the wheel rim, enabling seamless integration into various types of machinery.

For off-road conditions, the BM60 delivers up to 25,000 Nm of torque, and with its two-speed function, the working speed can be flexibly adapted to varying operating conditions. With Black Bruin’s mechanical freewheeling technology, the motor can rotate freely without active hydraulics, functioning as a conventional wheel hub when required. The feature is particularly useful during on-road transport.

Key features of the BM60 Wheel Motor

- Displacement: 2000 – 3500 cm3

- Max. power: 90 kW

- Max. torque: 25,000 Nm

- Max. pressure: 450 bar

- 1- or 2-speed option

- Internal freewheeling valve

- Speed sensor

- CTIS preparation

Compact drum brakes designed for easy maintenance

The BM60 motor is available with a high-performance hydraulic or mechanical drum brake.

Both brake options share the same key advantages: they fit compactly around the motor, forming an exceptionally space-efficient and service-friendly assembly. The brake drum can be removed without detaching the motor from the machine, providing easy access for cleaning, inspection, and maintenance.

The hydraulically operated drum brake provides excellent design flexibility for different machine configurations. This allows the motor to be installed in steering axles, for example in various types of harvesting machines.

New mechanical drum brake option for the B250 Wheel Motor

Trusted in agricultural and forestry applications since its launch in 2017, the market-proven B250 wheel drive now comes with a new mechanical drum brake option. Similar to the drum brakes introduced for the BM60 motor, the new brake combines a compact design with a service-friendly structure.

See also

For the love of technology and people

In recognition of your hard and innovative work, and loyalty for over 40 years: Black Bruin’s Golden Distributor Award presented to NAHI’s Kent Strand.

Black Bruin unveils new X-series radial piston hydraulic motors for heavy duty applications

The new X-series will meet market demand in various industrial applications, including recycling, marine and offshore, pulp and paper, construction, mining, and material handling.

Sustainable development draws power from respect

Most of us agree that technology is here to stay, no going back to the time without it. To save and restore the environment, more efficient and reliable technology is essential. As a 60-year-old innovation, Black Bruin hydraulic motors have indeed endured and are proud to be sustainable in the truest sense of the word.