Agritechnica 2023

Black Bruin launches upgraded hydraulic wheel drive systems at Agritechnica

The global agricultural machinery and supplier industry will be on show at Agritechnica from 12 to 18 November, demonstrating inspiration and solutions for the complex challenges of global crop production under the motto “green productivity”. Black Bruin is proud to be part of this with sustainable innovations to be showcased on Stand G18 in Hall 17.

The Black Bruin wheel motor was not invented more than 60 years ago by following the masses. And to this day, energy-efficient, durable and long-lasting products are at the very heart of Black Bruin’s operations. The radial piston motor with rotating housing design, combined with new technologies, offers many advantages to improve the productivity and sustainability of machines in the cultivation of fields. These include:

- Reduction of soil compaction

- Combination of several work steps

- Saving on fuel consumption through improved traction and reduced slip

- Optimized use of the season due to reduced dependency on the weather

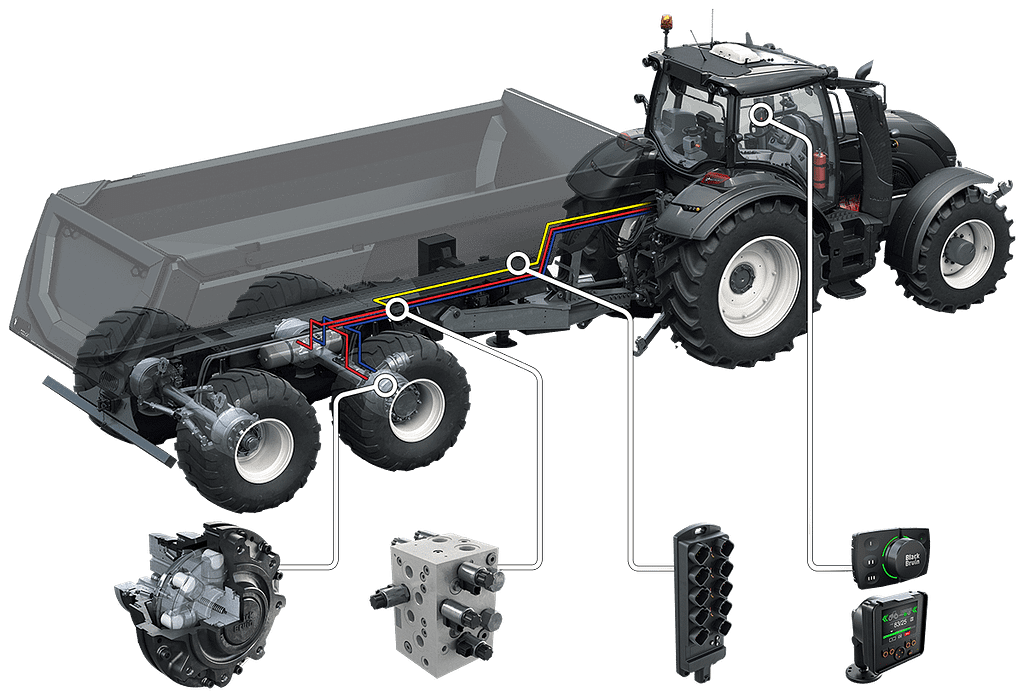

Hydraulic wheel drive system for trailers and implements

The Black Bruin On-Demand Drive System is a power transmission solution designed specifially for tractor-driven trailers and implements. The core of the system is formed by a hydraulic wheel hub motor, which provides tractive power exactly where it’s needed – right underneath the heavy load. The complete system also includes valves and control electronics and is ideal for use in agricultural, forestry and earth-moving applications. The system has already proven its benefits in multiple applications like slurry tankers, silage wagons, balers, potato harvesters, sprayers and forestry trailers.

“The importance of tractive power grows notably in demanding conditions and with bigger trailers and heavier loads. Professional contractors demand superior advancing capability of their equipment as well as controllability of the vehicle combination. Whatever the conditions, the job must get done,” Black Bruin’s Product Manager Tero Pelkonen explains.

“When the tractive power is distributed to 6 or even 8 wheels of a tractor-trailer combination, less counterbalance weight is required, and more traction can be achieved with less fuel consumption. Better traction reduces soil compaction and damages to cultivated areas. Consequently, this year’s as well as future yield is higher. Furthermore, you don’t need to be afraid of getting bogged down in soft or muddy soil, when the conditions are bad,” Pelkonen continues.

At Agritechnica, Black Bruin expands the concept and introduces its upgraded On-Demand Drive System | plus, which offer new features such as speed sensor support and a practical, CAN-based operating panel. For users, these updates enable more automated wheel drive control without having to use ISOBUS signal from the tractor and more usability for various operating situations. Black Bruin cooperates closely with manufacturers of trailers and axles as well as with system partners, continuously developing more productive and energy-efficient solutions for farmers and contractors.

“Our modular drive system with guaranteed component compatibility is easy to integrate, and we can also offer complete system support for the setup of a wheel drive system including control in our partner network. On example for this is the development of the Metsjö hooklift trailer drive,” Pelkonen concludes.

Wheel motors

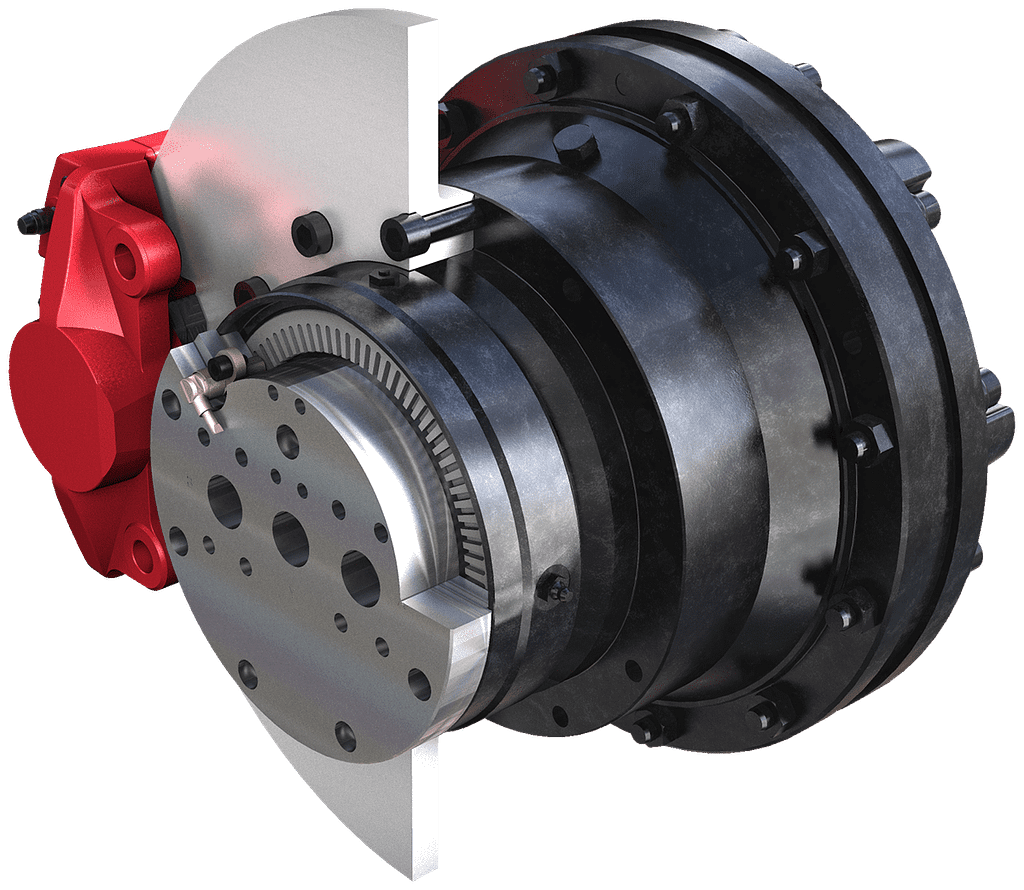

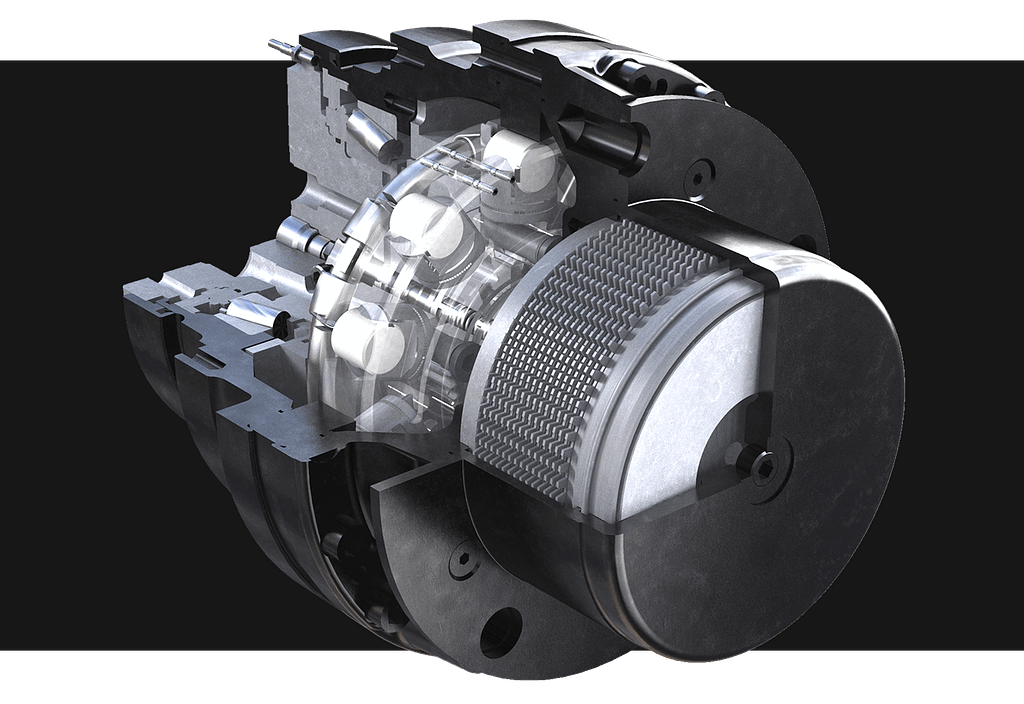

At Agritechnica, Black Bruin is also exhibiting its B200-series for trailers and implements and its new C200-series for efficient full hydrostatic drives. Black Bruin’s motor series are available with a comprehensive selection of service, parking and emergency brakes in compliance with the latest EU brake regulations. View brochure.

B200-series with upgraded options for trailers

B200-series wheel motors are designed to generate tractive power on tractor-driven trailers and implements. Due to their unique freewheeling technology, the motor can freewheel without active hydraulics and work as a conventional wheel hub. The B200-series motors transmit up to 130 kW of power and 45 kNm of torque. The displacement ranges from 500 to 6300 ccm with a high load carrying capacity of even up to 280 kN. These motors are available with drum and caliper disc brakes and new speed sensors with direction and motion detection.

New C200-series for full hydrostatic drives

The new C200-series motors are designed to deliver optimal power and efficiency for full hydrostatic transmission on mobile machinery. Whether it’s agricultural or forestry machinery, construction equipment or heavy-duty mining applications, these motors ensure smooth and reliable operation for better overall performance and productivity. Due to new materials and sealing solutions, these motors withstand high power with extended bearing lifetime and perform reliably in all kinds of off-road conditions. The C200-series motors transmit up to 90 kW of power and 22 500 Nm of torque. The displacement ranges from 462 to 3150 ccm. The C200-series motors are available with static and dynamic wet multi-disc brakes and caliper disc brakes. The track drives of mera Rabeler’s muR is an interesting example for the intelligent use of C200 motors.

So come and share your ideas with us. Let’s work together to make your applications more productive and sustainable. You are welcome to book an appointment in advance by contacting our team members.

Upcoming events

3

March 2026

CONEXPO-CON/AGG 2026

Las Vegas, USA

The largest construction show in North America.