S-series hydraulic motors

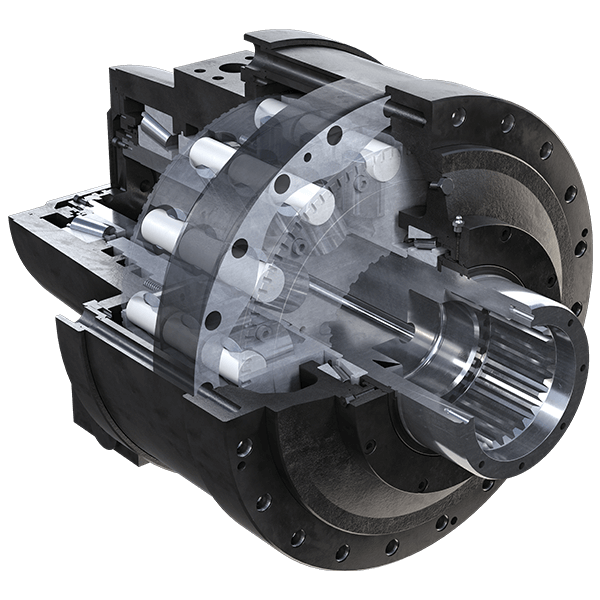

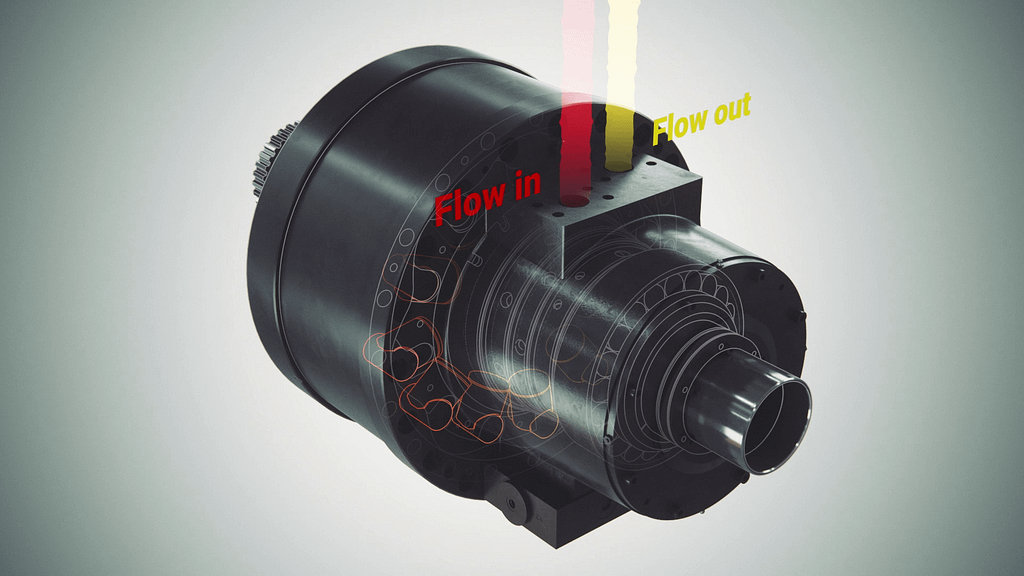

The S-series direct drive hydraulic motors are our response to the various needs in industrial applications to produce continuous high power efficiently without gears. The robust mechanical construction combined with serviceable torque-transmitting components is ideal for demanding applications like industrial shredders, drills, winches and conveyors.