Partnership

The Art(o) of knowing it inside out: HydroSystem is Black Bruin’s long-trusted partner in Finland

In gratitude for your hard work and commitment from 2000 to 2021. HydroSystem’s Arto Haataja deservedly receives Black Bruin’s Golden Distributor Award.

Black Bruin products and Finnish HydroSystem’s (HydSupply’s) Senior Advisor, Arto Haataja, started their journey together in 1985, when the original designers of the unique Black Bruin motors were all still around. Cordial relationships between these hydraulics gurus have endured throughout all these years, although sadly some members of the group have already joined the great hydraulics master upstairs.

But there’s a lot of stamina and great memories involved. In January 2020, Mr. Turkka Raita’s 85th birthday was celebrated on the selfsame spot in front of the old imperial Russian barracks where the forerunner of the Black Bruin motor, ”SISU”, drew its first breath.

An impressive growth story

Arto has been with HydroSystem for over 20 years. Established in 1986, for a few year it was a one-man company, until in the early 90’s it started servicing SISU motors. Arto joined the company as a part owner and fifth employee in 2000. After the other owners retired, the company shifted entirely into Arto’s capable hands, where it stayed until 9 years ago, when it was sold to the Swedish industrial automation group Volito Automation, and Arto stayed on as an employee. Volito also became the Black Bruin distributor in Sweden in connection with the HydroSystem purchase.

And as of 1 January 2021 a brave new structure with a dedicated brand for MRO in Finland, HydSupply Oy. Arto is excited about the current changes in the structure of the group and has promised to help see them through, whereafter he plans to retire, because ”nobody lasts forever”, as he says with a lively twinkle in his eyes.

Arto played a significant role in the adoption of the Black Bruin name, replacing the earlier Valmet name for the motors: The name was initially used to refer to one product – at an exhibition in 1996 – and later, in 2016, it became the name for the entire company. In fact, the name was originally Black Bear, but because that name was already being used by another company in the US, the new name was Black Bruin.

Black Bruin, and the original SISU motors were the first brand HydroSystem were responsible for servicing, but gradually, with more muscle, HydroSystem´s operation expanded to cooperation with other big international companies, first Parker and then Danfoss. Several big brands have been showing interest in HydroSystem’s offering for some time due to the company’s excellent reputation.

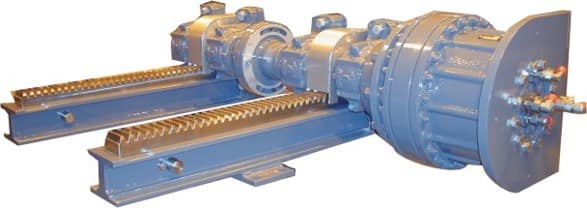

Manufacturing, updating and upgrading

A big part of HydroSystem’s operations has been MRO-based, and that’s what the new brand HydSupply is all about. Ten years ago the manufacturing of Black Bruin motor’s predecessor, SISU motor, was transferred to HydroSystem. The SISU motor is intended solely for industrial applications. Since the Satatekniikka company joined the Volito Automation Group a year ago, operations have tended increasingly towards industrial applications and their servicing. ”We go wherever hydraulics, pneumatics and automation are in use,” says Arto Haataja and lists branches familiar to the company: ” The paper industry, the sawmill industry, the metal industry, the chemical industry”.

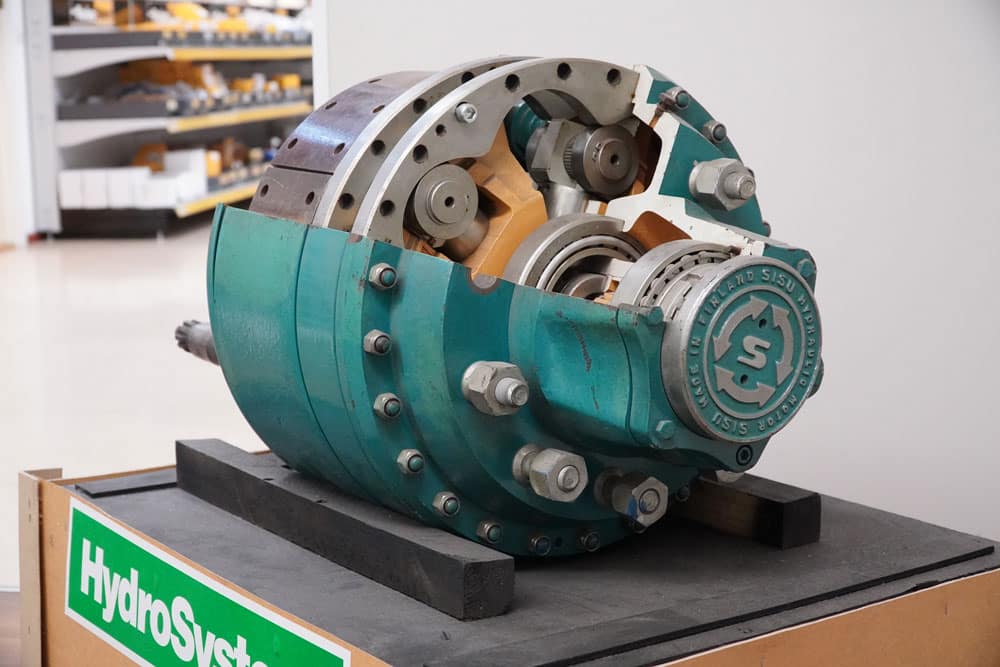

In cooperation with Black Bruin, the SISU motor has extended its life span far into the future. SISU is a unique high starting torque – low hysteresis motor suitable for certain applications, particularly papermaking processes, for which there is no viable alternative in any manufacturer’s range. It is HydroSystem’s mission to manufacture, assemble and market the SISU motors globally. They have all the necessary storage, maintenance capability and knowhow. Manufacturing of the most vital components of the motor and its machining is handled continuously by Black Bruin.

Right from the beginning, HydroSystem has been involved with the most recent Black Bruin, the S-series, which differs from the original SISU motor, and is intended for different industrial applications. HydroSystem frequently updates and upgrades an existing process with the S-series.

Strong commitment

With more discussions and engagement, the Swedish corporate culture differs somewhat from the Finnish way of doing things. As an experienced entrepreneur, Arto favours prompt action and feels that even after the takeover, he has had the opportunity and also the support to develop business to the direction he has regarded as the best, but with this time also with group perspective in mind. The Swedish approach favours collective decisions,” says Arto and continues: ”The especially positive aspect of this is that everybody is committed and stands behind the decisions made.” And the decisions taken collectively by HydroSystem and Volito Automation have been demonstrably good ones. The figures are proof of that.

Niche translates into great potential

The industry itself is pretty conservative and there is a resilient continuity in the technological solutions. Arto has great faith in the Black Bruin S-series and its expansion to even more applications. ”There’s certainly a lot of potential for that,” Arto states confidently. He remembers vividly how in 1986, Black Bruin embarked on its first harvester head application. This led to conquering a whole new branch and a solution that other manufacturers sought to copy.

One clear trend is that the OEMs want to be in closer contact with the manufacturers of hydraulics solutions and produce more services for the end users. Hydraulics is not in their own core knowhow; they prefer to leave that part of their production to the motor supplier so that they can concentrate more on producing truly versatile services. This then means that there will always be a need for companies which excel in such a niche branch and offer a range of products to cater for it.

Brothers in arms

There’s been fairly active employee exchange between HydroSystem and Black Bruin over the years. There’s a gentlemen’s agreement between the two companies not to headhunt the other’s employees or harm each other’s business in any way, but if somebody wants to move from one company to the other, it is considered to strengthen the total skills and offering and help to retain skilled workforce in the ”Black Bruin bubble” – and develop their capabilities further. ”We have a good and cordial partnership with Black Bruin,” says Arto with appreciation.

Knowing it inside out

HydroSystem’s MRO services consist mainly of well-planned predictive maintenance for big corporations over a long lifecycle. There are basically two kinds of services: field maintenance on site and component maintenance at HydroSystem’s workshop, which may also involve HydroSystem’s sister companies. Maintenance of a hydraulic motor generally involves rebuilding, where the motor is ”dismantled into atoms”, washed and inspected, parts in need of renewal ascertained. Only genuine and original parts may be used. Sometimes an update is needed to replace and make a component better than it was originally.

The workshop needs to know which originally good but currently obsolete parts are not worth putting back but need to be replaced by a new solution from product development. After this, the piece of equipment needs to be test run and it needs to be as good as new, or even better. This calls for knowhow and also a large operating volume so that all possible fault situations can be diagnosed.

Arto describes HydroSystem’s role in the big picture: “For component maintenance, you need to know the product inside out, understand what is critical and what is not, be absolutely sure about the tolerances and measurements, even the most confidential technical details. After repair and assembly you still need testing equipment for trial runs. It takes quite a lot of knowhow and equipment to get it exactly right.

Arto at large

Arto has two homes, one in the Tampella area in Tampere – once the home of great engineering workshops – and the other in the more rural Laukaa, near Jyväskylä where he can spend his free time exploring the nature and wildlife on the lake shore while the seasons change. The day before the interview, Arto caught a hazel grouse – not by shooting it, but because it flew into the living room window of their house and did not survive the impact, luckily not breaking the window. Arto also spends time dreaming, reading, playing the guitar, doing forestry, hiking and playing with his grandchildren. A busy pensioner-to-be.

The Swedish group Volito Automation’s MRO-segment in Finland will be managed via the new brand HydSupply Finland from 1 January 2021. The new brand will replace the two existing brands Satatekniikka and HydroSystem. With the merger of the two brands into HydSupply we become a larger and an even more competitive organization, which means that we can manage larger projects. HydSupply now stands prepared for the future, committed to be the customers first choice for high quality automation solutions and services.

See also

Demanding North American customers in focus for 40 years – NAHI and Black Bruin

North American Hydraulics has been Black Bruin’s trusted partner for practically 40 years. Amidst hurricanes and viruses, one thing has always been and will be vital for both: stay focused on the demanding customer.

Trailers and motors for a specific purpose: BMF and Black Bruin cooperate and please demanding farmers and forest professionals

BMF is the highly successful forest trailer brand of Estonian company OÜ Lisako, which annually produces approximately 1 000 trailers with cranes for forestry use. The company aims to increase the share of larger and more high-end trailers every year. And so far, they are well on their way to doing just that - with some help from Black Bruin.

HOF in Thailand: Your partner for a better tomorrow

“With our own product ranges combined with Black Bruin motors, we can offer a complete hydraulic system for certain applications. The opportunities in South East Asia for Black Bruin are huge and completely untapped."